Posted on July 2, 2004

I have long been in awe of the beautiful and creative designs that people have created for the mini-itx form factor. Unfortunately I am a destructive force when paired with a tablesaw or dremel drill. So I searched around for projects that wouldn't require powertools and come up with the Mini-Mesh Box, which required nothing more destructive than a pair of wire cutters and a bottle of glue.

|

The resulting system is cool and quiet (no problems with venting!), and is currently acting as a PVR for my TV room.

Parts List

The main ingredient for my project was a mesh wire box with a hinged cover that I found at the local stationery store. It is designed to hold a ream of paper, and is roughly 9X12x2 inches in size.

Other parts that went into this project came from local computer, electronics, and hardware stores:

• Nehemiah EPIA M 10000 motherboard

• PW-80 80 watt PSU of the type that mounts directly on the board, plus the external 12V brick

• 256 Mb stick of PC2100 DDR RAM

• A 20 Gb IBM Travelstar 2.5 inch hard disk, and a slimline DVD/CD-RW, both salvaged from a dead laptop.

• 3.5" to 2.5" IDE adaptors for the hard disk and DVD/CD-RW

• Pushbutton switches

• 1/4" hexagonal standoffs

• Assorted LEDs and mounting retainer rings

• Crimp-style connector housings and ribbon cable

• Components for a serial port-based infrafred detector as described here

• A quieter 40 mm fan to replace the one that comes with the M10000

• A translucent vinyl report cover

• Miscellaneous screws and washers

Mounting the Motherboard

|

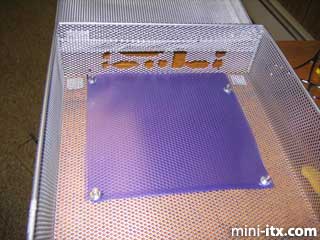

An issue with the mesh box is that the bottom is flexible, allowing it to bow upward and short out the motherboard. To avoid this eventuality, I cut two 17x17 cm sheets of translucent vinyl from a plastic report cover. During the preparation of the mesh box I used one of these as a template for cutting holes for the mounting screws. Later the two plastic sheets became electrical insulators between the motherboard and the box.

Using the template as my guide, I snipped two small holes in the mesh box underneath the mounting holes in the motherboard. I then screwed the standoffs in from below. The image above shows how the standoffs mount.

Now came the most time-consuming part of the project, cutting the holes for the backpanel ports. I used the metal backplate provided by VIA to trace the port pattern onto another piece vinyl, and taped the vinyl to the mesh. Then I started work with my wire cutters.

About an hour later, surrounded on all sides by tiny sharp pieces of waste metal, I placed the motherboard into the box, and behold, it fit!

After mounting the board, I discovered that there remained just enough room to allow placing a PCI card using a riser board. However, when closed, the back rim of the mesh box would interfere with any ports protruding from the card. A few swift strokes of the hacksaw solved this problem without seeming to affect the structural integrity of the box or its lid.

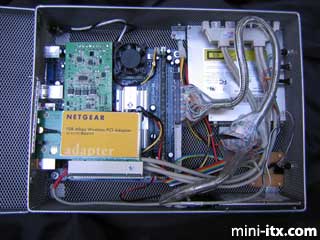

If you look closely, you can see a small slot cut in the mesh just a bit to the left of the main opening for the PCI card. This slot accomodates the protruding lip of the PCI card's rear metal plate. The slot supports the lid nicely, preventing the card from wiggling around. The photograph below shows how the PCI slot looks when occupied by a CardBus bridge and a wireless card. I have since replaced the cardbus card with a PCI-based wireless card.

|

|

|

|

Quick Links

Mailing Lists:

Mini-ITX Store

Projects:

Show Random

Accordion-ITX

Aircraft Carrier

Ambulator 1

AMD Case

Ammo Box

Ammo Tux

AmmoLAN

amPC

Animal SNES

Atari 800 ITX

Attache Server

Aunt Hagar's Mini-ITX

Bantam PC

BBC ITX B

Bender PC

Biscuit Tin PC

Blue Plate

BlueBox

BMW PC

Borg Appliance

Briefcase PC

Bubbacomp

C1541 Disk Drive

C64 @ 933MHz

CardboardCube

CAUV 2008

CBM ITX-64

Coelacanth-PC

Cool Cube

Deco Box

Devilcat

DOS Head Unit

Dreamcast PC

E.T.PC

Eden VAX

EdenStation IPX

Encyclomedia

Falcon-ITX

Florian

Frame

FS-RouterSwitch

G4 Cube PC

GasCan PC

Gingerbread

Gramaphone-ITX-HD

GTA-PC

Guitar PC

Guitar Workstation

Gumball PC

Hirschmann

HTPC

HTPC2

Humidor 64

Humidor CL

Humidor II

Humidor M

Humidor PC

Humidor V

I.C.E. Unit

i64XBOX

i-EPIA

iGrill

ITX Helmet

ITX TV

ITX-Laptop

Jeannie

Jukebox ITX

KiSA 444

K'nex ITX

Leela PC

Lego 0933 PC

Legobox

Log Cabin PC

Lunchbox PC

Mac-ITX

Manga Doll

Mantle Radio

Mediabox

Mega-ITX

Micro TV

Mini Falcon

Mini Mesh Box

Mini-Cluster

Mobile-BlackBox

Moo Cow Moo

Mr OMNI

NAS4Free

NESPC

OpenELEC

Osh Kosh

Pet ITX

Pictureframe PC

Playstation 2 PC

Playstation PC

Project NFF

PSU PC

Quiet Cubid

R2D2PC

Racing The Light

RadioSphere

Restomod TV

Robotica 2003

Rundfunker

SaturnPC

S-CUBE

SEGA-ITX

SpaceCase

SpacePanel

Spartan Bluebird

Spider Case

Supra-Server

Teddybear

Telefunken 2003

TERA-ITX

The Clock

ToAsTOr

Tortoise Beetle

Tux Server

Underwood No.5

Waffle Iron PC

Windows XP Box

Wraith SE/30

XBMC-ION