or "Roll-Your-Own" Network Attached Storage Device

Posted on October 4, 2003

Parts List

• Quantum Snap Server 2000 Case

• VIA EPIA 800 Mini-ITX Motherboard (800Mhz)

• 512MB PC133 DIMM

• Flex ATX-090 PSU

• 10.05GB IBM Travelstar 4,200RPM Laptop Hard Drive x 7

• SIIG Ultra ATA/133 Low-Profile

IDE Controller

• Sony CRX700E CD-R/RW Drive

• Laptop CD-ROM to IDE Adapter

• 40- to 44-pin Laptop Hard drive Converter x 4

• 2mm 44-pin IDE Ribbon Cable(in

feet) x 5

• 44 Pin Male Plug Type IDC Connector x 3

• 44 Pin Female Socket Type IDC Connector x 6

• 60mm 3-pin Fan for Hard Drive Array

• Right-Angle

PCI Extender

• LEDs, Screws, Aluminum Plates, Reset & Power Buttons, Miscellaneous

The first step was taking the Faraday shield out of the "Snap Server" labelled side of the case to use as the hardware mounting tray. In order to maximize usable space in the case, I used a Dremel to cut away the vent grill on the front of the Faraday shield / tray.

A quick test fit of the VIA motherboard in the tray to get an idea of MB placement. Some of the Faraday cage contacts along the top of the tray had to be folded down to provide clearance for the SIIG IDE controller.

Adding the I/O shield and four 1/4-inch, hexagonal standoffs to the motherboard allowed me to mark the cut out lines for the rear of the hardware tray.

A quick run of the Dremel along the guidelines and a bit of filing gives a nice, smooth edge.

Another fitting of the motherboard to mark the forward edge of the motherboard in the tray and where the motherboard mounting holes will go. Then drill the holes and attach the standoffs.

Using a small piece of a breadboard PCB, I added the LEDs for the System power, Network activity, Link, and Disk activity.

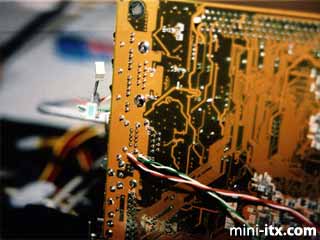

Since the Mini-ITX board doesn't have additional headers on it for the front panel lights (hint, hint to the engineers at VIA), I had to add my own. You have to be VERY careful when soldering wires to the appropriate spots on the motherboard. I recommend using a 15W soldering iron to prevent damaging components that are in proximity to the solder points. In this image you can see the lights on the left during a test.

In order to avoid cluttering the inside of the case with cables and blocking air-flow, I routed the IDE cable for the CD-RW under the motherboard (the cable to the left). The cable going to the right was my original attempt to connect the hard drives for the OS.

At this point, the motherboard is ready for mounting on the hardware tray.

|

|

|

Quick Links

Mailing Lists:

Mini-ITX Store

Projects:

Show Random

Accordion-ITX

Aircraft Carrier

Ambulator 1

AMD Case

Ammo Box

Ammo Tux

AmmoLAN

amPC

Animal SNES

Atari 800 ITX

Attache Server

Aunt Hagar's Mini-ITX

Bantam PC

BBC ITX B

Bender PC

Biscuit Tin PC

Blue Plate

BlueBox

BMW PC

Borg Appliance

Briefcase PC

Bubbacomp

C1541 Disk Drive

C64 @ 933MHz

CardboardCube

CAUV 2008

CBM ITX-64

Coelacanth-PC

Cool Cube

Deco Box

Devilcat

DOS Head Unit

Dreamcast PC

E.T.PC

Eden VAX

EdenStation IPX

Encyclomedia

Falcon-ITX

Florian

Frame

FS-RouterSwitch

G4 Cube PC

GasCan PC

Gingerbread

Gramaphone-ITX-HD

GTA-PC

Guitar PC

Guitar Workstation

Gumball PC

Hirschmann

HTPC

HTPC2

Humidor 64

Humidor CL

Humidor II

Humidor M

Humidor PC

Humidor V

I.C.E. Unit

i64XBOX

i-EPIA

iGrill

ITX Helmet

ITX TV

ITX-Laptop

Jeannie

Jukebox ITX

KiSA 444

K'nex ITX

Leela PC

Lego 0933 PC

Legobox

Log Cabin PC

Lunchbox PC

Mac-ITX

Manga Doll

Mantle Radio

Mediabox

Mega-ITX

Micro TV

Mini Falcon

Mini Mesh Box

Mini-Cluster

Mobile-BlackBox

Moo Cow Moo

Mr OMNI

NAS4Free

NESPC

OpenELEC

Osh Kosh

Pet ITX

Pictureframe PC

Playstation 2 PC

Playstation PC

Project NFF

PSU PC

Quiet Cubid

R2D2PC

Racing The Light

RadioSphere

Restomod TV

Robotica 2003

Rundfunker

SaturnPC

S-CUBE

SEGA-ITX

SpaceCase

SpacePanel

Spartan Bluebird

Spider Case

Supra-Server

Teddybear

Telefunken 2003

TERA-ITX

The Clock

ToAsTOr

Tortoise Beetle

Tux Server

Underwood No.5

Waffle Iron PC

Windows XP Box

Wraith SE/30

XBMC-ION